R & D base

Research and

development base

forging

forging

Five forging production lines, including:

3150T hot die forging in Russia × 1

2500t hot die forging in Russia × 2

1600t electric screw press × 1

80kj CNC hammer × 1

The medium frequency heating furnace of each forging line is equipped with temperature control and three-way screening device

The forging process of hole making and edge making is at the advanced level in China

2500t hot die forging in Russia × 2

1600t electric screw press × 1

80kj CNC hammer × 1

The medium frequency heating furnace of each forging line is equipped with temperature control and three-way screening device

The forging process of hole making and edge making is at the advanced level in China

Heat

treatment

treatment

heat treatment

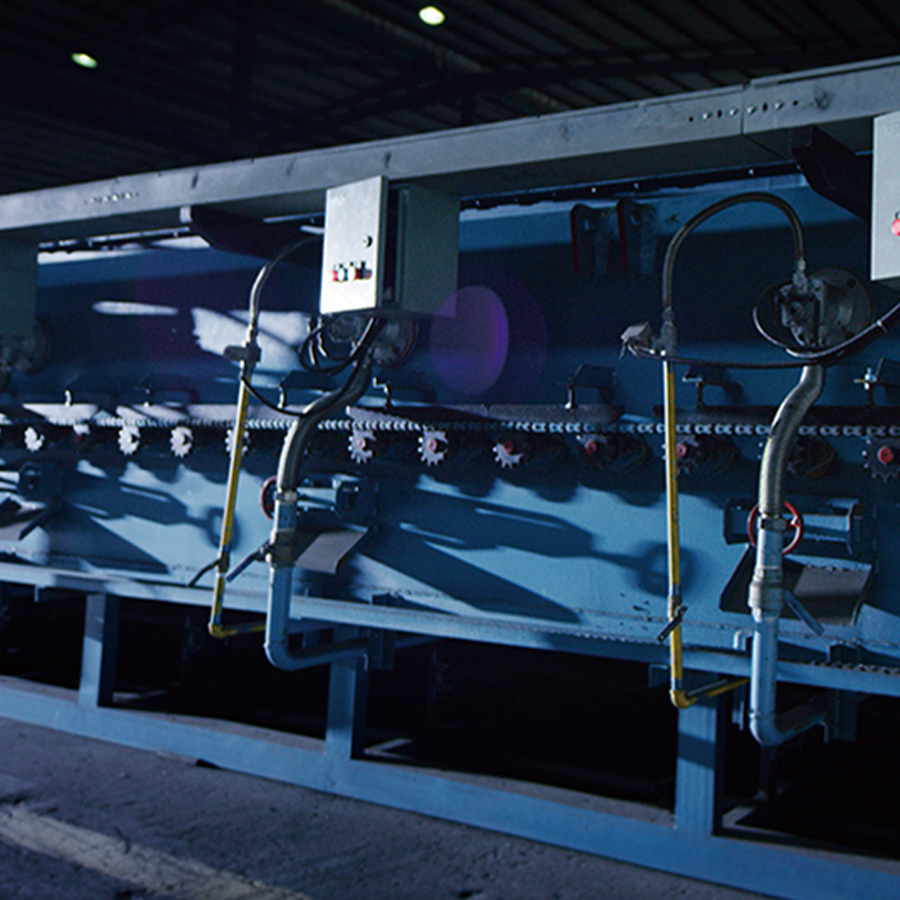

Continuous heat treatment line of mesh belt furnace × 7

Rail surface intermediate frequency processing line × 5

Magnetic particle inspection equipment × 7

All heat treatment and intermediate frequency treatment are in strict accordance with the OEM standard of the host

Rail surface intermediate frequency processing line × 5

Magnetic particle inspection equipment × 7

All heat treatment and intermediate frequency treatment are in strict accordance with the OEM standard of the host

machining

Machining

Japan Mazak machining center × 2

Hass machining center × 1

Integrated special machine with chain rail link × 2

Chain rail link split type special aircraft line × 10

Mini chain link special machine × 3

Matching processing, one clamping to complete all processes,

In addition to the completion of accurate product processing dimensions, the most rigorous to ensure the shape and position tolerance of products.

Hass machining center × 1

Integrated special machine with chain rail link × 2

Chain rail link split type special aircraft line × 10

Mini chain link special machine × 3

Matching processing, one clamping to complete all processes,

In addition to the completion of accurate product processing dimensions, the most rigorous to ensure the shape and position tolerance of products.

assembly

assembling

Chain rail assembly line × 8, including:

Korea automatic line × 2

Domestic automatic line × 3

Chain oiler × 2

Dry chain grease injection machine × 5

Constant torque of double shaft

Track shoe tightening machine × 2

Domestic automatic line × 3

Chain oiler × 2

Dry chain grease injection machine × 5

Constant torque of double shaft

Track shoe tightening machine × 2

R & D Center

Research and

development base

Brand culture

Our experimental staff have rich experience and rigorous style

Brand culture

We have various professional experimental instruments

Brand culture

Quality comes from rigorous product design, perfect process and strict quality control

Brand culture

To investigate, analyze and compare the similar products in the market, and constantly improve ourselves in the competition

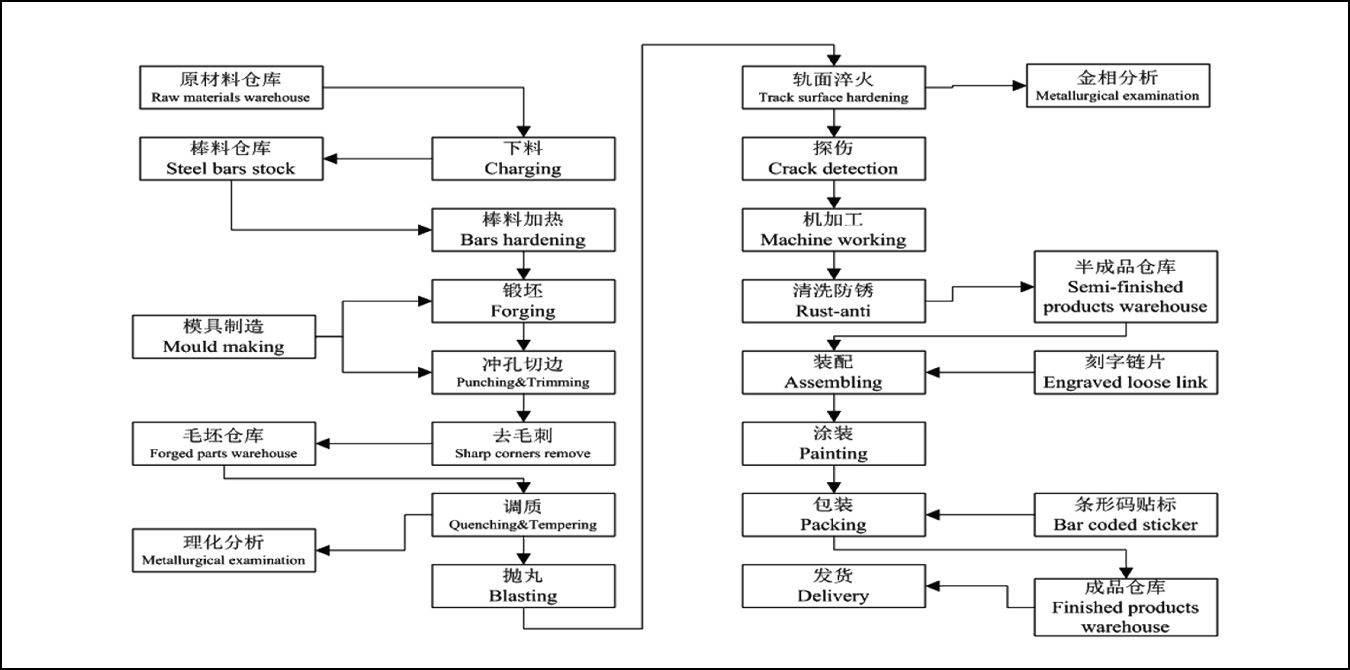

Process route

Process route

●Each batch of raw materials has undergone physical and chemical experiments

●The heating temperature of each bar is strictly controlled

●Metallographic analysis was carried out for each batch of heat treatment

●Every chain rail link has been inspected

●Each chain has a unique code for traceability